Hydraulic Shock Absorbers

All hydraulic shock absorbers work by the principle of converting kinetic energy (movement) into thermic energy (heat). For that purpose, fluid in the shock absorber is forced to flow through restricted outlets and valve systems, thus generating hydraulic resistance.

A telescopic shock absorber (damper) can be compressed and extended; the so called bump stroke and rebound stroke.Telescopic shock absorbers can be subdivided in:

- Twin-tube, or bi-tube, dampers, available in hydraulic and gas-hydraulic configuration.

- Mono-tube dampers, also called high pressure gas shocks.

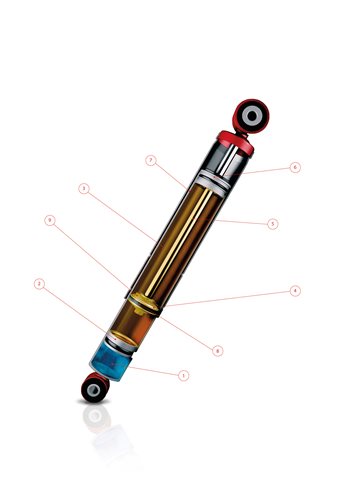

How does a twin-tube shock absorber work?

Bump stroke

When the piston rod is pushed in, oil flows without resistance from below the piston through the orifices and the non-return valve to the enlarged volume above the piston. Simultaneously, a quantity of oil is displaced by the volume of the rod entering the cylinder. This volume of oil is forced to flow through the bottom valve into the reservoir tube (filled with air (1 bar) or nitrogen gas (4-8 bar). The resistance, encountered by the oil on passing through the footvalve, generates the bump damping.

Rebound stroke

When the piston rod is pulled out, the oil above the piston is pressurized and forced to flow through the piston. The resistance, encountered by the oil on passing through the piston, generates the rebound damping. Simultaneously, some oil flows back, without resistance, from the reservoir tube (6) through the footvalve to the lower part of the cylinder to compensate for the volume of the piston rod emerging from the cylinder.

The main components are:

- outer tube, also called reservoir tube (8)

- inner tube, also called cylinder (7)

- piston (2) connected to a piston rod (3)

- bottom valve, also called footvalve (6)

- piston rod guide (5)

- upper and lower attachment

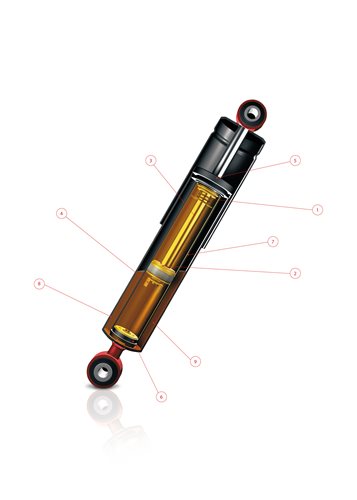

How does a mono-tube shock absorber work?

Bump stroke

Unlike the bi-tube damper, the mono-tube shock has no reservoir tube. Still, a possibility is needed to store the oil that is displaced by the rod when entering the cylinder. This is achieved by making the oil capacity of the cylinder adaptable. Therefore the cylinder is not completely filled with oil; the lower part contains (nitrogen) gas under 20 – 30 bar. Gas and oil are separated by the floating piston (2)

When the piston rod is pushed in, the floating piston is also forced down by the displacement of the piston rod, thus slightly increasing pressure in both gas and oil section. Also, the oil below the piston is forced to flow through the piston. The resistance encountered in this manner generates the bump damping.

Rebound stroke

When the piston rod is pulled out, the oil between piston and guide is forced to flow through the piston. The resistance encountered in this manner generates the rebound damping. At the same time, part of the piston rod will emerge from the cylinder and the free (floating) piston will move upwards.

The main components are:

- (pressure) cylinder, also called working cylinder (7)

- piston (4) connected to a piston rod (5)

- floating piston, also called separating piston (2)

- piston rod guide (6)

- upper and lower attachment